What are 1018 Low Carbon Mild Steel? AISI 1018 is the primary obtainable of the cold-rolled steels in the market. It is usually obtainable in various shapes of bars. It has a virtuous amalgamation of all of the characteristic qualities of steel i.e. easy machining, formability, weldability and strength. On the basis of chemical composition, it is very close to SPHC Hot Rolled steel, but subsequent cold working process produces a improved surface finish and enhanced properties. Being a mild steel; 1018 cold rolled steel has low carbon content for it yields a uniform and tougher item and it is related as the paramount steel for carburized components. AISI 1018 cold rolled steel comprises a virtuous equilibrium of stiffness, plasticity and tensile strength.

Dimensional Characteristics of 1018 Low Carbon Mild Steel: The applicable thickness in millimeters for this 1018 Low Carbon Mild Steel ranges from 0.125 to 1.5 for cold rolled quality whereas the width in millimeters is from 600 to 1200, also available in various slit forms of varying width. Moreover different sizes & shapes of bars (Rectangular, flat, round, square, hexagonal etc) available as per customer demands.

Available Forms in Market: Following are the available forms of 1018 Low Carbon Mild Steel:

- Bars in Various shapes

- Slitter Coils

- Sheets & Plates

- Milled Coils

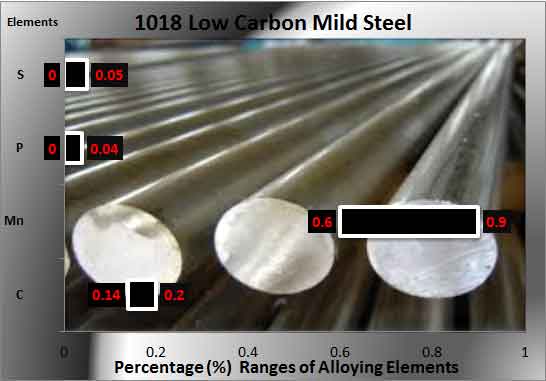

The Chemical Composition of 1018 Low Carbon Mild Steel: Chemical alloying compositions are explicated below

- Maximum percentage of Carbon as defined in the standard is 0.2 whereas Minimum percentage of Carbon as defined in the standard is 0.14

- Maximum percentage of Manganese as defined in the standard is 0.9Image may be NSFW.

Clik here to view.

- Maximum percentage of Phosphorus as defined in the standard is 0.04

- Maximum percentage of Sulphur as defined in the standard is 0.05

Spotlight: Advanced industrial processes are utilized for surface making, element configuration, hot & cold rolling and heat treatment controls. All these procedures ripe superlative eminent mild steel that are well-matched to fabrication methods for example surface treatments, drawing, welding, piercing, forming, and forging.

Mechanical Properties of 1018 Low Carbon Mild Steel: Mechanical properties are as under

- Hardness in HRB as specified in technical sources is maximum 71.

- Tensile strength is maximum 440 Mpa in some technical sources.

- Yield strength is maximum 370 Mpa in some technical sources.

- Elongation is 15% in 50 mm in the standard.

Equivalent Materials of 1018 Low Carbon Mild Steel: The equivalent materials for 1018 Low Carbon Mild Steel specified in other recognized standards are listed as under

- In EN standard, the equivalent material is referred as EN32B type steel.

- In UNS standard, the equivalent material is referred as G10180 type steel.

Industrial Applications of 1018 Low Carbon Mild Steel: These are used in variety of industrial applications including

- Gears, pins in Carburized state

- Die Parts, Tool Fixtures, machine components

- Drilled & Threaded Components

- Bending Components for Assembly

- Ratchets, Studs & Bolts

Comparative Materials: Some nearly matching materials are discussed below:

- SPCC Steels: SPCC steels are cold rolled steels which are a very close match to SAE 1018 steel, but SPCC steels have lower carbon and these are less hard than AISI 1018. So if one needs a less hard steel SPCC steel can take the place of 1018.

- ISO 3574 CR1 Steels: CR1 steels are also cold rolled commercial quality and these are almost equivalent to SPCC grade hence therefore can substitute 1008 material on the same basis.

Suppliers List for 1018 Low Carbon Mild Steel : There are many suppliers for this type, some are listed below:

- Premium supplier name is Tianjin Baotai Teyuan International Trade Co., LTD, Contact information is 60990883 and postal address is Beichen District,Tianjin,China.

- Secondry supplier name is M & K Metal, Contact information is 310-327-9011 and postal address is 14400 Figueroa St. Gardena, CA 90248.

Note: These values are indicative and for information purpose only. Some of the given information can be outdated. There are also minor possibilities for inaccuracies in the text due to human error. For inaccuracies & outdated text you can e-mail & inform the Content Manager at materialgrades@yahoo.com